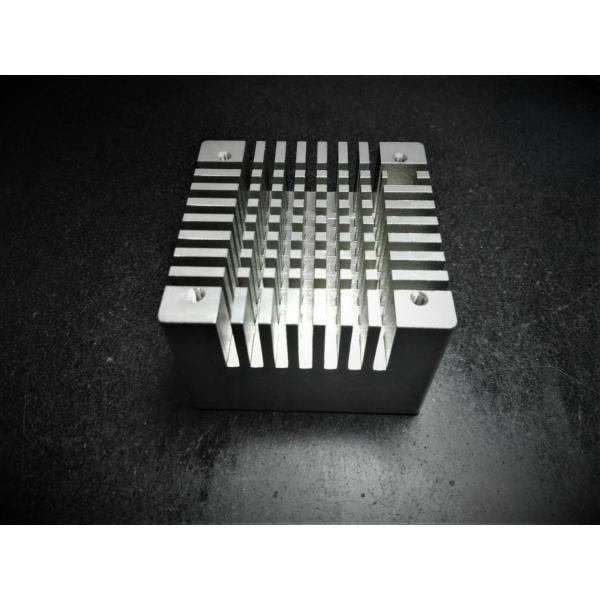

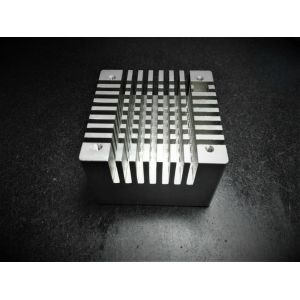

PCB Housing Custom Cnc Machined Components Bracket Raw Aluminum

Parts

Product Details:

Custom Machining PCB Housing Raw Aluminum Parts CNC Miling

Aluminium Machinery Parts

Bracket parts Mountaineering Equipment Parts

Material: AL7075 Surface:Anodizing Concentricity:0.02mm

Rugosity:Ra0.8 Tolerance:0.01-0.02mm L*W*H(mm)=52mm*52mm*41mm

Metal:2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.SKD11,DC53.

Plastic(POM, PEEK, PP)

Machine:CNC processing center,Wire cutting macine,Milling

machine,Grinding machine,EDM.

Surface treatment:nickel plating,chrome plating,anodizing.

Purpose:Communication equipment,Testing equipment,Electronics

equipment,agricultural

machinery,electrical appliances products,Generator parts,Bathroom

Parts,Ship accessories,

Electric Tool Parts,Monitoring equipment,Communication

Equipment,Audio Equipment Parts,

Digital Camera Parts,Mining Machinery Parts,Petroleum Mining

Machinery Parts,Bridge

structural parts,Microscope Bracket Parts,Juice extractor

parts,Mountaineering Equipment Parts,

Fishing gear parts,Sports Equipment Parts,Fitness Equipment

Parts,Photographic equipment parts,

Furniture Hardware Parts,Mower Parts

Main Products Display

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | | Bakelite | flame plating |

| F141 | | A7075 | | Teflon | Abrasion |

| CK45 | | Others | | Others | Chemical polishing |

| Others | | | | | Others |

| Heat Treatment |

| treatment | Conditioning treatment | High cycle quenching |

| Passivation | quenching treatment | Carburizing treatment |

| Stress Removal Passivation | Vacuum quenching treatment | salt-bath nitrocarburizing |

| Annealing treatment | Tempering | |

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring

you the most reliable,efficient and affordable metal component.our

highly skilled and professional workforce is dedicated to

satisfying the individual needs of all our customers and various

markets the serve. |

| Processing type |

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

| Application | Precision machinging,Unmanned aerial vehicle & aerospace,Motor &

pump,Robotics,medical devices,Optical communication,Rotary

Union,Automotive,3D Face Recognition System,Tools and Fixtures,Gear

& screw,hardware fasteners & Bolt & Shaft | Customized drawings | AutoCAD,JPEG,PDF,STP,IGS, and most other file formats are accepted. |

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production

way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with

customer.

4) Checking the process, machine, and other details in the

production line.

5) Checking every products before packing them.

6) Checking the package before delivery.

FAQ:

Q1: Can XINYA make technical drawings for my design?

A1: We can provide a drawing for Manufacturing review according to

your current 2D,3D CAD draft or a

sample offered by you. We of course will sign and adhere to any

non-disclosure or confidentiality agreement

if your design is confidential.

Q2: How long can I get a quotation?

A2: We respond within 24 hours when receive an RFQ. Normally a

quotation will take 1-3days. If there is

delayed, we will notify you as soon as possible.

Q3: How quickly can I get my parts?

A3: Lead times is normally 2-3 weeks when get your complete 2D and

3D CAD models from the order date.

Complex parts requiring or large quality order will take longer.We

are able to be competent for some urgently

needed project as well.As for shipping, most of our shipments are

via Express or by Air, which will take

3-7days to your door.

Q4: What after-sales service can I get for any unsatisfied parts I

receive?

A4: To ensure high quality of our machined components, we have

detailed quality control system and full-

equipped measuring equipments. We guarantee all the dimension based

on the information provided by you.

We have confidence in our ability to meet and exceed any reasonable

expectations.

Q5: Environmentally friendly materials have been used, and how does

it work?

A5: The material corresponding to RoHS regulation and reach in

Europe is available and is actually used.

For each material, if you have a request to use the material for

the environment from customers, we propose

a suitable material and process it based on the decision.

Q6: Is the material readily available?

A6: Depending on the material. The procurement / T is somewhat

different, and most of the materials can

be delivered on the next business day. However, it may be difficult

to incorporate materials in such cases

because it is often disturbed by the price of materials and the

effect of social conditions.

Q7: Worried about the scars on delivery,

etc?

A7: Please rest assured. Beanut bag, partition, cushioning

material, tray, corrugated cardboard, wooden box,

etc.are firmly packaged in the form of packing. It is thought that

there are various bad conditions during

transportation such as bad weather, unpaved road, trouble driving,

and collapsing. Even if there is such

an unexpected event, I try to do the packing which does not affect

the product.

Q8: Can I have a check repot?

A8: Yes, of course. We inspect the dimensions of each item of the

extracted item according to the number

of products to the inspection of our regulations, and decide

whether it is possible or not. ]The quality control

department can be said to be the last defensive wall for not

putting out the defective product outside the

company.

Q9: Can We assemble it?

A9: Yes, We can am good at mechanical assembly. The technique of

joining multiple

parts with one shot and the best mechanical assembly

Q10: Is there no problem with size change due to heat treatment?

A10: The change of dimensions is different depending on the

processing method, time and quantity.

There is no mistake until the processing of the metal does not

leave the hand of our company. Therefore,

even if it is a plating one, the company may instruct the film

thickness and the color. Heat treatment is also

big strain. We will take a look at the strain and then put the

Grinding or change the heat treatment method.

Of course,We have get the understanding from customer, and there is

a case that the proposal of such as

"how do I do this way" in many years experience?

Q11: How long is the quotation valid?

A11: The Quotation valid for 30 days. The unit price will not

change unless there is a significant change in

the material cost and exchange rate. However, according to the

rules established by our company, we have

to reestimate it for 30 days.

Q12: Can I get the ingredient sheet and other data of the

materials?

A12: Yes, we can provide the ingredient sheet and date MSDS of

materials, well as the issued by the material

manufacturer according to the customer's requirements.

Quality policy

Quality manufacturing we strive for perfection,we maintain good

technical

interaction with suppliers and customers with efforts to drive for

quality excellence in our products,we take

pride in every of our manufacturing and management process to

eliminate errors and deficiencies .

We understand that customer's satisfied with the quality and

service is an important indicator of successful

companies.The way the company wins depends on high-precision

machine for high quality requirements

of various components.

It is our goal to meet our customers’ expectation through good

quality, fast delivery service,

productivity and continuous improvement.Shenzhen Xinya Precsion

Machining Co., Ltd.

is to be your best choice and long-term partner.